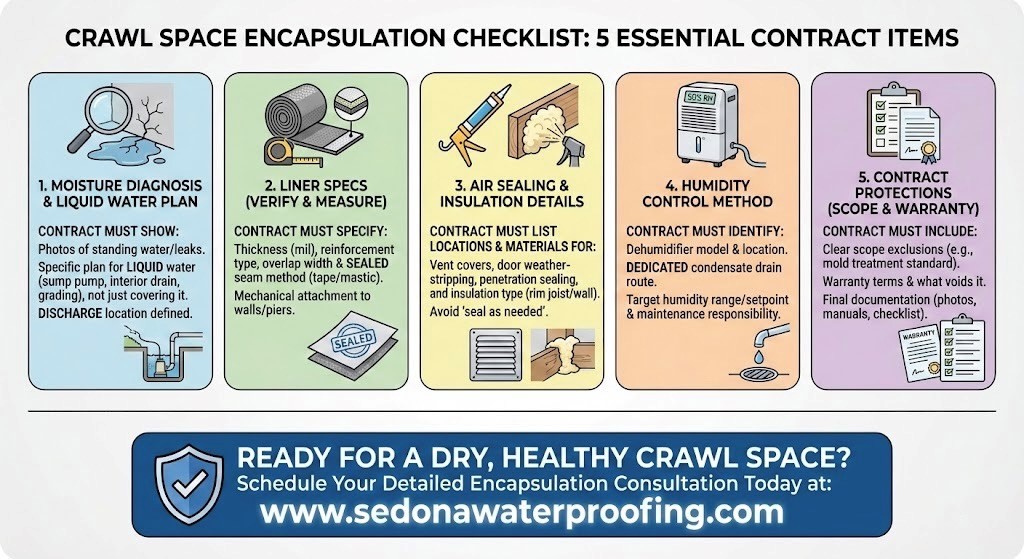

Crawl Space Encapsulation Checklist: Don’t Sign a Contract Without These 5 Things

If you’re collecting estimates, a crawl space encapsulation checklist keeps the conversation grounded in specifics. Encapsulation is a system that blocks soil moisture, manages liquid water, tightens leaky openings, and keeps humidity under control after the space is sealed. The contract is where you find out whether a company is selling a system or just rolling out plastic.

Below are five contract items worth checking off before you sign.

Table of Contents

Toggle1) A written moisture diagnosis and a plan for liquid water

A good proposal starts with “why is it wet?” not “here’s our package.” Your contract should note what the inspector observed, ideally with photos: standing water, wet soil, staining, leaks, or damaged insulation.

Then look for a plan for liquid water. That can include downspout extensions, grading, plumbing repairs, or an interior drain and sump. If the work includes a pump, the scope should name the discharge location and who handles electrical power.

If the bid skips this step, you risk sealing in a recurring water problem.

2) Crawl space encapsulation requires liner specs you can verify

“Vapor barrier included” is not a specification. The contract should name liner thickness, reinforcement, seam method, and attachment details. The Department of Energy calls out basics like overlapping and taping seams and sealing the material up the walls to limit soil moisture migration.

Ask the contractor to spell out:

- Thickness and whether the liner is reinforced.

- Seam overlap and the tape or sealant used.

- How the liner is fastened at walls, piers, and penetrations.

- How they protect the liner in service paths.

One useful tell is whether they describe vapor barrier installation (crawl space) as a set of steps (corners, columns, pipes), not a single line item.

Many building codes require exposed earth in an unvented crawl space to be covered with a continuous vapor retarder, with joints overlapped and sealed. Having those details in the contract gives you an objective standard for inspection: you can lift a corner of tape, check overlaps, and confirm that soil is not left bare behind pipes or at the perimeter.

3) Air sealing and insulation details, not vague promises

Encapsulation often includes closing vents and air leaks, but quality varies. ENERGY STAR stresses prep and air sealing because materials only stick to clean, sound surfaces.

Your contract should name:

- How vents will be closed and sealed.

- How the access door will be weather-stripped.

- Which penetrations will be sealed.

- Where insulation will go and what material will be used.

If the scope mentions crawl space sealing (vents / air leaks), it should also list locations and products. “Seal as needed” invites shortcuts and disagreements.

4) A humidity-control method that fits the home

Once you tighten a crawl space, you need a way to remove moisture that remains. Many sealed crawl spaces use controlled exhaust, a small HVAC supply, a dehumidifier, or a combination, depending on climate and the home’s HVAC setup. Research reports better summer moisture performance in sealed crawl spaces in certain homes.

The contract should identify:

- The selected method and where equipment will sit.

- The condensate drain route.

- A humidity target or setpoint range.

- Maintenance responsibilities.

If the plan includes a crawl space dehumidifier, the scope should list the model and drain method. A unit that can’t drain reliably becomes another source of water.

5) Contract protections: scope boundaries, pricing logic, and proof

Encapsulation costs vary because homes vary. The fair question is “what exactly am I buying?” Your contract should include a step-by-step scope, clear exclusions, and a change-order process for surprises.

Look for:

- Whether mold treatment is included, and to what standard.

- Warranty terms and what voids the warranty.

- What documentation you receive at the end (photos, manuals, checklist).

Ask how the bid accounts for conditions that drive crawl space encapsulation cost, such as access height, debris removal, liner grade, drainage work, and mechanical drying.

When to pause before you sign

Encapsulation is not the first move when bulk water is still entering, plumbing leaks are active, or framing has rot that needs repair. Covering up wet conditions can trap problems where you can’t see them.

It is also wise to discuss any combustion appliances that draw air from the crawl space, since tightening the space can change airflow patterns.

Finally, ask where water will go during a severe storm. The scope should include crawl space waterproofing / water management measures if the home has a history of intrusion.

Also Read: Crawl Space Encapsulation in North Carolina: Turning Upfront Dollars into Decades of Dividends

Frequently Asked Questions:

- When should you not encapsulate a crawl space?

Hold off when liquid water is still entering, such as standing water after rain, repeated flooding, or active plumbing leaks. Pause if structural repairs are needed first. Also pause if fuel-burning equipment depends on crawl-space air and no one has evaluated combustion safety. Fix water and safety issues, then revisit sealing.

- What do I need to encapsulate my crawl space?

Most projects include debris removal, a ground liner sealed at seams and run up foundation walls, closed vents, and sealed air leaks. Many homes also need drainage improvements and a humidity-control method after sealing. ENERGY STAR’s guide highlights prep work, seam detailing, and directing water to a drain point. It can also improve comfort in rooms above.

- How thick should the vapor barrier be, and how should it be installed?

Thickness depends on durability needs, but installation details matter more than the number on the label. Energy guidance recommends overlapping seams, taping them, and sealing the material up the crawlspace walls to reduce soil moisture migration. Ask for thickness, overlap, tape type, and wall attachment in writing.

- Do sealed crawl spaces always need a dehumidifier?

Not always. Some use controlled exhaust or a small amount of conditioned air instead. The right choice depends on climate, the home’s HVAC design, and local expectations. What matters is that the contract names the method, shows how moisture will be removed, and includes a drain route and service plan.

- Will encapsulation reduce mold and musty odors?

Often it helps, but only when moisture sources are controlled and the sealed space stays dry. If mold is already present, the scope should include cleaning or remediation where needed, plus long-term humidity control. Done well, this supports crawl space mold prevention and lowers the chance that odors return.

Recent Posts

- Crawl Space Encapsulation Checklist: Don’t Sign a Contract Without These 5 Things

- The Stack Effect: Why 50% of the Air You Breathe Comes from Your Crawl Space

- Why Carbon Fiber is the Most Sustainable Choice for Modern Basements in Charlotte NC

- Designing for Dampness: How to Create a Luxury Basement That Can Handle a Flood

- Why Floors Feel Spongy or Bouncy After Heavy Rain (And What to Do About It)

Categories

- Basement Mold

- Basement Waterproof Foundation

- Basement Waterproofing

- Crawl Space Dehumidifier

- Crawl Space Encapsulation

- Crawl Space Encapsulation Cost

- Crawl Space Repair

- Crawl Space Waterproofing

- Crawl Space Waterproofing and Encapsulation

- Encapsulation

- Foundation Repair

- Foundation Waterproofing

- French Drains

- Leaky Basement

- Mold Remediation

- Mold Removal

- Radon

- Radon and Moisture

- Slab Jacking

- Sump Pump

- Uncategorized

- Vapor Barrier

- Water Leak

- Waterproofing

- White Mold

Archives

- February 2026

- January 2026

- December 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- March 2025

- August 2024

- June 2024

- May 2024

- March 2024

- January 2024

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019